meho7

Vu+ Newbie

Hello

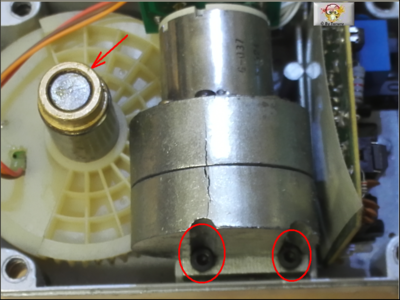

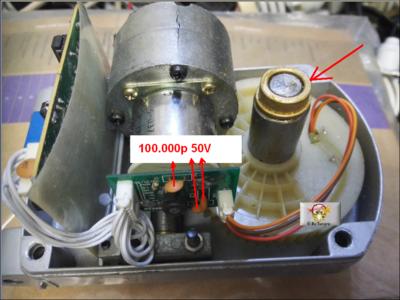

After a few years of usage my old Moteck SG2100 got faulty (wouldn't turn - clicking noises)

I've replaced it with a Stab hh120.

Now here's where the problems start.

The first problem is im getting really low signal from strong positions - for example on Astra 19.2° channel is ZDF i only get 70% while before i got close to 100%(it's the same with 9e AFN only 61% , Hotbird 13e too). I tried everything (changed inclination/elevation, tried moving it) I have no idea what the problem could be.

Then there's the second one. When I try to move from position A to B - for example going from 0.8w to 7e the motor moves the dish a few degrees further. I've tried fine tuning in the Vu+ tuner settings, stored the position and it still goes a few degrees over meaning it doesn't lock.

So what could be the problem? Faulty Vu tuner? Could it be the cables? Maybe the LNB?

This thing is really stressing me out.

After a few years of usage my old Moteck SG2100 got faulty (wouldn't turn - clicking noises)

I've replaced it with a Stab hh120.

Now here's where the problems start.

The first problem is im getting really low signal from strong positions - for example on Astra 19.2° channel is ZDF i only get 70% while before i got close to 100%(it's the same with 9e AFN only 61% , Hotbird 13e too). I tried everything (changed inclination/elevation, tried moving it) I have no idea what the problem could be.

Then there's the second one. When I try to move from position A to B - for example going from 0.8w to 7e the motor moves the dish a few degrees further. I've tried fine tuning in the Vu+ tuner settings, stored the position and it still goes a few degrees over meaning it doesn't lock.

So what could be the problem? Faulty Vu tuner? Could it be the cables? Maybe the LNB?

This thing is really stressing me out.